SUMMARY

Maintaining quality double seams is an essential part of food and beverage canners’ operations. A leaking double seam must be avoided.

VISUAL INSPECTION

Visually inspecting the external double seam is a valuable tool in maintaining double seam quality. In food canning processes, visual inspection of each container is performed from each seaming station at least every 30 minutes. While traversing around the seam, the inspector is looking for deviations in the double seam. Typical problems found visually include seam vees and droops. Seam bumps are difficult to see because the deviation is small. In practice, visual inspections identify 80% to 90% of seam quality problems.

DOUBLE SEAM INSPECTION

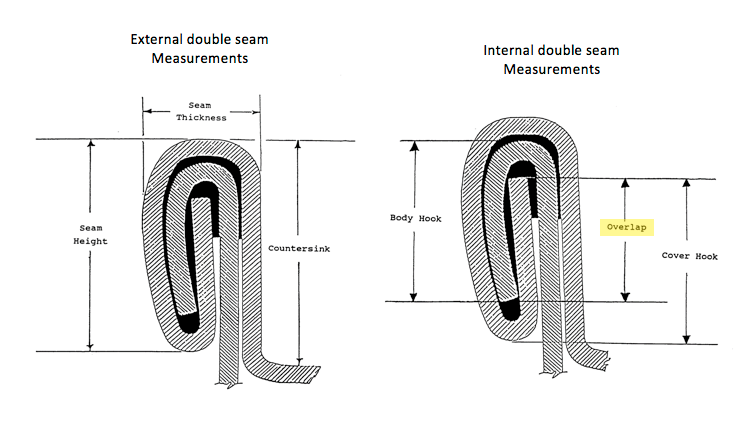

The SeamMate® System records and tracks precision internal double seam measurements, helping the quality assurance and maintenance staff maintain, predict and ensure double seam quality. Inspecting the cross section is a very effective method because you are measuring the actual internal dimensions of the double seam components including the critical seam overlap. The overlap dimension is critical because too-short overlap dimensions can result in a leaking double seam. Internal dimensions of double seams for each seamer head are measured and recorded at least every 4 hours.

SeamMate® System walks the operator through the specified double seam measurements: seam thickness, countersink, precision video measurements of seam height, body hook, cover hook and overlap.

Because seam components interact, a change in one dimension will typically affect another dimension. For example, a change in the body hook dimension will change the overlap dimension. Monitoring % Butting helps maintain correct relationships among double seam components. % Butting is especially important in maintaining overlap and body hook. % Butting measurements are easily setup in the SeamMate® System.

In this example:

% Overlap = 0.049/Butting Dimension

% Body hook = Net Body hook/Butting Dimension

% Cover hook = Net Cover hook/Butting Dimension

Seam tightness is a critical measurement that is difficult to determine because the inspector is visually evaluating the unwrinkled length of the cover hook as a percentage of the total length. This rating is based on the worst individual point on the cover hook. A looseness wrinkle can be seen on the cover hook after the seam has been torn down for inspection. Looseness wrinkles, as they appear on the cover hook, project toward the body hook or outward from the center of the can. Normal looseness wrinkle can be characterized by its three-dimensional attributes: wrinkle exhibiting width, depth, and amplitude.

Automatic Seam Tightness™

Correctly evaluating tightness is critical to maintaining double seam quality. The engineering team at OneVision has developed a patented method to measure seam tightness from the captured seam image! This new automatic tightness measurement does not replace manual wrinkle rating. It provides added confidence in estimating the wrinkle rating from the double seam cross-section.

A double seam is defined as follows:

A hermetic seal is formed by interlocking the edges of both the end component and body of a can. It is commonly produced in two operations. The first operation forms the metal to provide the five thicknesses or folds, and the second operation flattens or irons these components to produce the required seal.

Double Seam Terminology (Internal) Double Seam Terminology (External)

It is imperative to have a good first operation seam as it is impossible to form a quality finished seam unless the first operation seam is correct. A correctly formed first operation is a major key to the control of the cover hook which in turn partially controls the body hook as well as the countersink depth and degree of wrinkle in the cover hook. A poorly formed first operation seam cannot be corrected by the second operation roll(s). It is recommended that first operation seams be checked weekly or when seam problems occur.

First operation seams will determine the length of the finished second operation seam. Typically, as the first operation roll groove profile gets narrower, the seam height begins to shorten. Wide profiles will yield longer seam heights.

A useful rule of thumb is to closely observe the bottom portion of the first operation seam. It should have a smooth radius with minimal scuffing.

The Second Operation Formation is the final operation in double seaming. In this operation, the double seam components formed in the first operation are ironed or flattened, compressing the compound to fill the voids not occupied by metal.

The lower compound tunnel should be filled with compound as this tunnel provides the primary seal. The upper tunnel acts as a reservoir for excess compound and may not always be filled with compound.

The tightness of the double seam is determined by evaluation of the degree of wrinkle in the cover hook section.

**A double seam must be evaluated in its entirety and not by dimensions alone.

Sequence of Operation

The tightness rating attributed to a double seam is established by evaluating the unwrinkled length of the cover hook as a percentage of the total length. This rating is based on the worst individual point on the cover hook. A normal looseness wrinkle can only be seen after the seam has been torn down for inspection. Looseness wrinkles, as they appear on the cover hook, project toward the body hook or outward from the center of the can. Normal looseness wrinkle can be characterized by its three dimensional attributes: wrinkle exhibiting width, depth, and amplitude.

Reverse Wrinkle

A Reverse Wrinkle is a non-tightness type of wrinkle that projects towards the can body wall or the center of the can. A reverse wrinkle is formed in the first operation seam and cannot be ironed out regardless of the tightness of the second operation seam. Reverse wrinkles typically appear when seaming harder alloy and/or lighter gauge and stock.

Reverse wrinkles, in themselves, are an appearance issue. They do not attribute to leaker spoilage unless the material folds over on itself (Pucker or Pleat) and/or cracks vertically.

One should not try to impose a grading system for this condition. Individual situations must be assessed, and a decision made on each separate case.

Calculation of overlap length:

Overlap Length = CH + BH + T – SH

Where CH = Cover Hook

BH = Body Hook

T* = Cover Plate Thickness

SH = Seam Height (Width or Length)

*In general practice, .010″ may be used for the cover thickness. However, for accuracy, the actual plate thickness of the cover should be used.

Calculation of percent overlap:

Overlap % = 100 x (BH + CH + T – SH) / [SH – ((2 x T) + BPT)]

Where BH – Body Hook Length

CH = Cover Hook Length

T = Cover Plate Thickness

SH = Seam Height

BPT = Body Plate Thickness

Use minimum value found for each measurement (maximum value for SH).

Calculation of overlap length:

Body Hook Butting % = A / B x 100

IT IS RECOMMENDED OVERLAP AND BODY HOOK BUTTING BE OPTICALLY MEASURED.

Seam Impression (Pressure Ridge) is caused by the force of the seaming rolls pushing the cover hook material against the bottom of the seaming chuck, resulting in an impression on the inside of the can body.

This feature cannot and should not be taken on its own as an indication of adequate tightness.

**Some roll profiles and chuck designs will not yield a significant seam impression. This is also true of seams produced with light gauge metal, aluminum and double reduced (DR) body and end plate.

**Heavy seam impression can fracture coatings that could lead to leaker spoilage. Make sure seam is not overly tight.

Need a quote or interested in learning more?

Fill out the form and we will be in touch.