SeamMate® System

A turnkey and comprehensive can seam inspection solution.

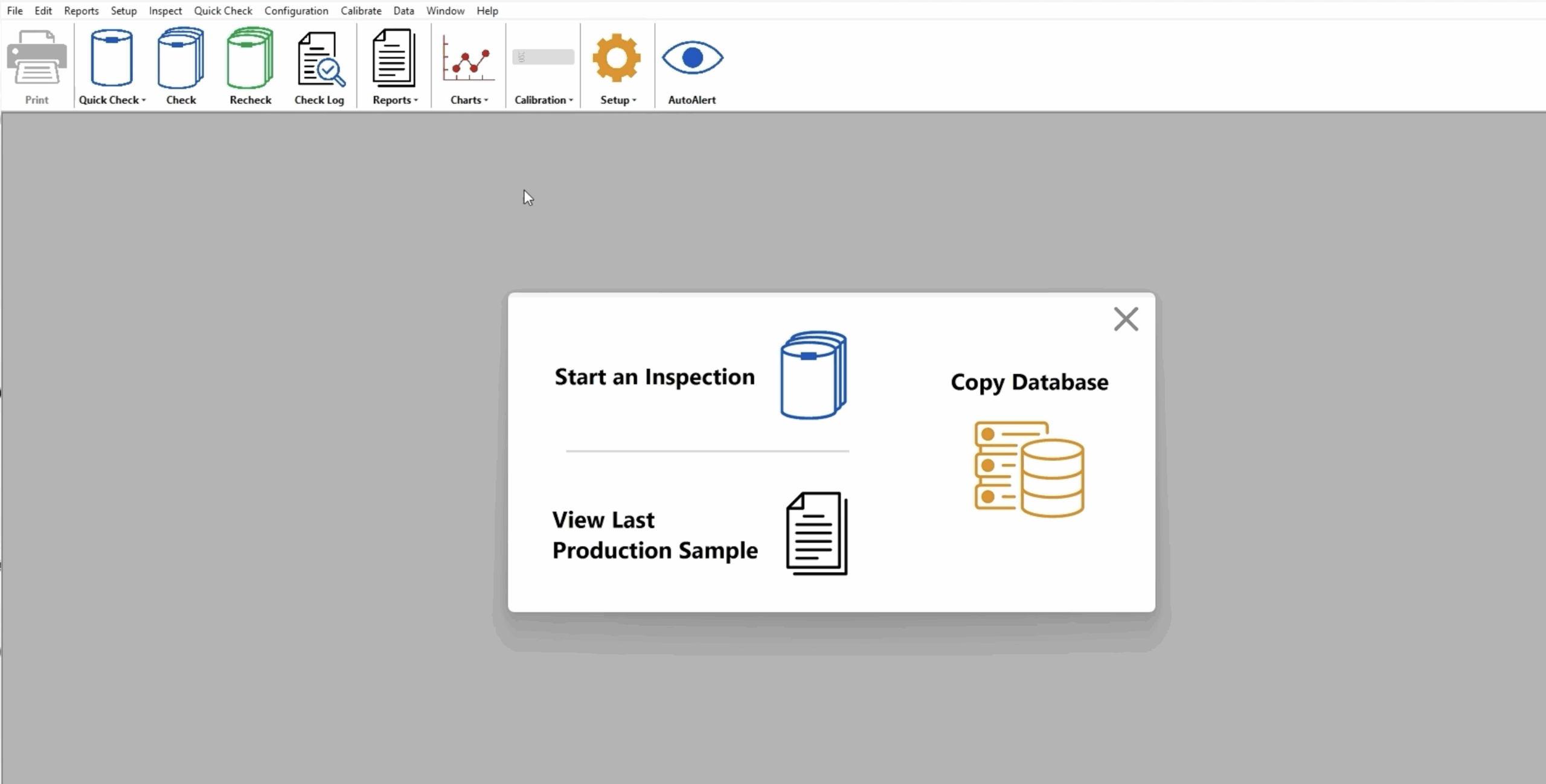

Simplicity, reliability, and precision are our standards for double seam inspection. OneVision’s SeamMate® System is the canning industry’s most powerful turnkey can seam inspection system to check double seams and provide easy-to-use information to ensure double seam quality.

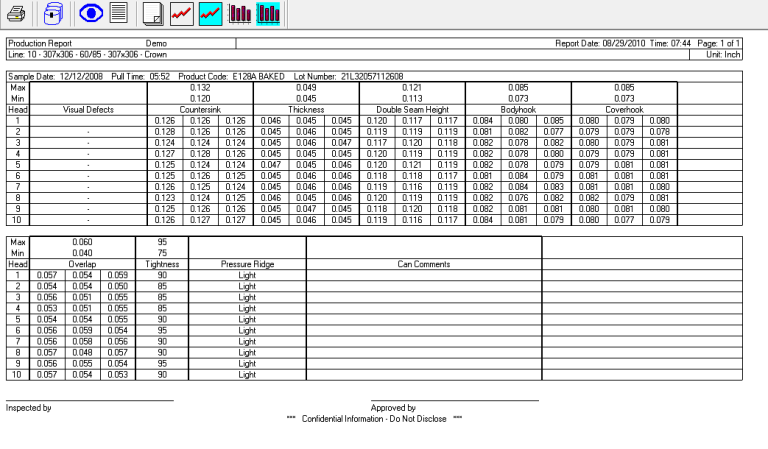

Standard setup automatically measures countersink depth, seam thickness, body hook, cover hook, overlap, seam height and automatically calculates % overlap and % body hook butting. Additional measurements such as automatic seam tightness, compression, and free space can be enabled.

Double Seam Inspection

OneVision’s seam vision systems, gauges, and inspection products provide accurate data on critical dimensions and visual characteristics of your double seams. The SeamMate® System provides information that helps your company maintain and predict double seam quality. By delivering both predictive and preventive intelligence, SeamMate becomes an effective tool to help achieve continuous process quality improvement.

Features

• Automatically compares double seam measurements to specifications, records, and visually alerts inspectors of issues

• Easily print and export images and reports. e-Signature of inspection reports available for all installed systems in 2026.

• Database storage for all can specifications and measurements

• Fast, accurate user-friendly gauge systems

• Easy access to data for meaningful display, analysis or reporting

• Easy-to-use SPC graphics with OneVision’s AutoAlert process tracking

• Seamer Condition at a glance on desktop using SeamVision

• Fits your networked environment

Process Control System

The SPC software upgrade empowers your team to predictively monitor your double seams.

• Statistical Process Control (SPC) calculations and charts included

• AutoAlert™ enables users to set thresholds which trigger alarms to help ensure double seam quality

• SeamVision™ visually displays seamer head performance based on AutoAlert™ alarm conditions

• Work Station enables editing of process specifications on non-inspection station PCs on plant network

• Report Station enables viewing of all reports on non-inspection station PCs on plant network

Specifications

• Built-in high-precision video microscope and thickness gauge

• Includes countersink gauge

• HD digital camera

• Durable stainless steel (Pro 400 video module)

• Multiple LED seam illumination

• Automatic seam brightness

• Automatic dimensions in under 1/4 second

• Patented Automatic Seam Tightness measurement

• Includes a Windows 11 PC Package or software can be installed on customer-supplied PC