What Is A Double Seam and Why Is It Important?

A Double Seam is a hermetic seal formed by interlocking edges of both the end component and body of a can. In the most basic sense, a proper double seam maintains the quality and prolongs the shelf life of a canned good.

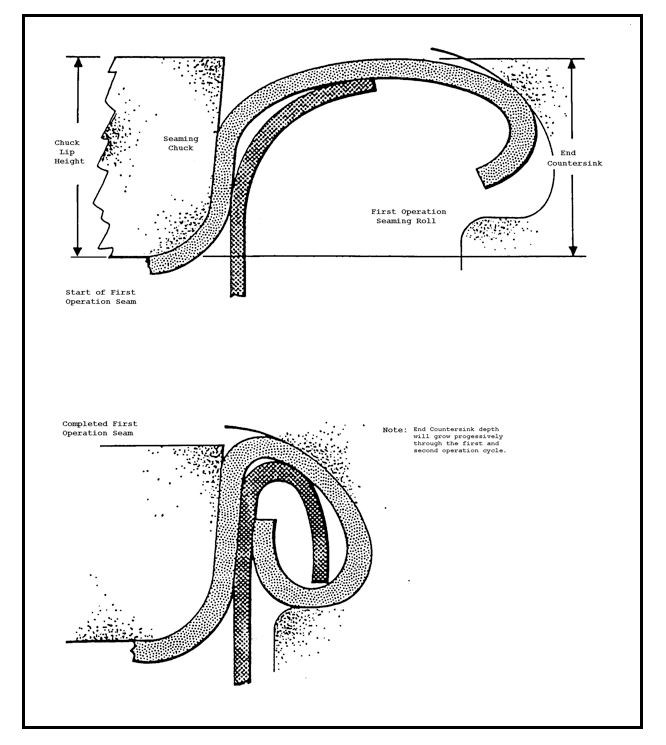

A can’s double seam is formed in two operations, simply named first operation and second operation. The below image visually depicts the start of the first operation seam and what a good first operation seam should look like when complete. Achieving a quality first operation seam is imperative and cannot be corrected by the second operation seaming process. It is highly recommended that first operation seams be checked weekly or when seaming problems occur.

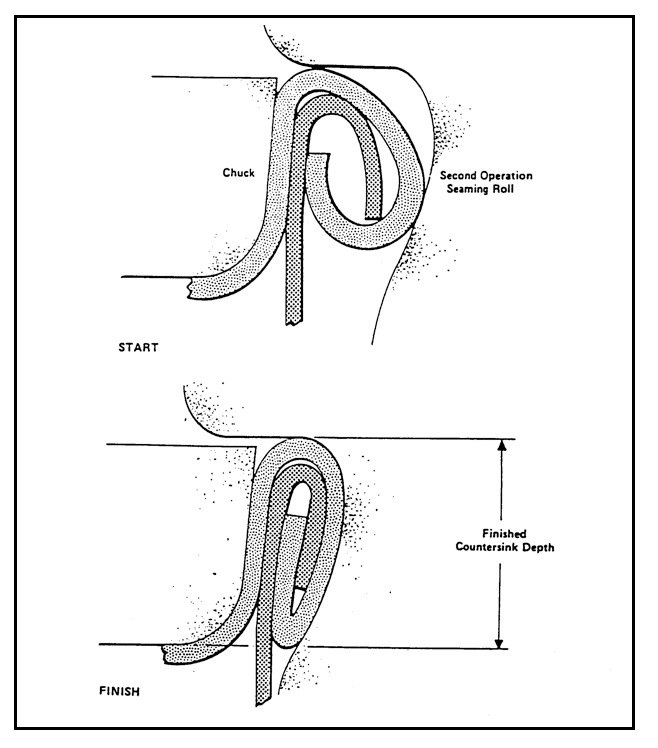

The final or second operation formation is the process of ironing or flattening out the double seams that were formed during the first operation. During this process, compound is compressed to fill voids not occupied by the can’s metal. The below image depicts the start of the second operation and what the seam should look like if rolled correctly.

It is imperative that beverage and food canners evaluate formed double seams on a regular basis to ensure quality of canned goods.

A number of double seam defects can occur during the seaming process. Click here to learn more about common seam defects.

Recent Comments